Contufilt-AC

Advanced Activated Carbon Filtration Solutions

Upgrade to an efficient, closed-system CONTUFILT-AC — a powerful, candle-less sparkler filter that enhances activated carbon filtration system productivity. Designed to eliminate mess and improve safety.

Complete Closed System

No by-pass

Effective Filtration

Recover 90 - 99% resource

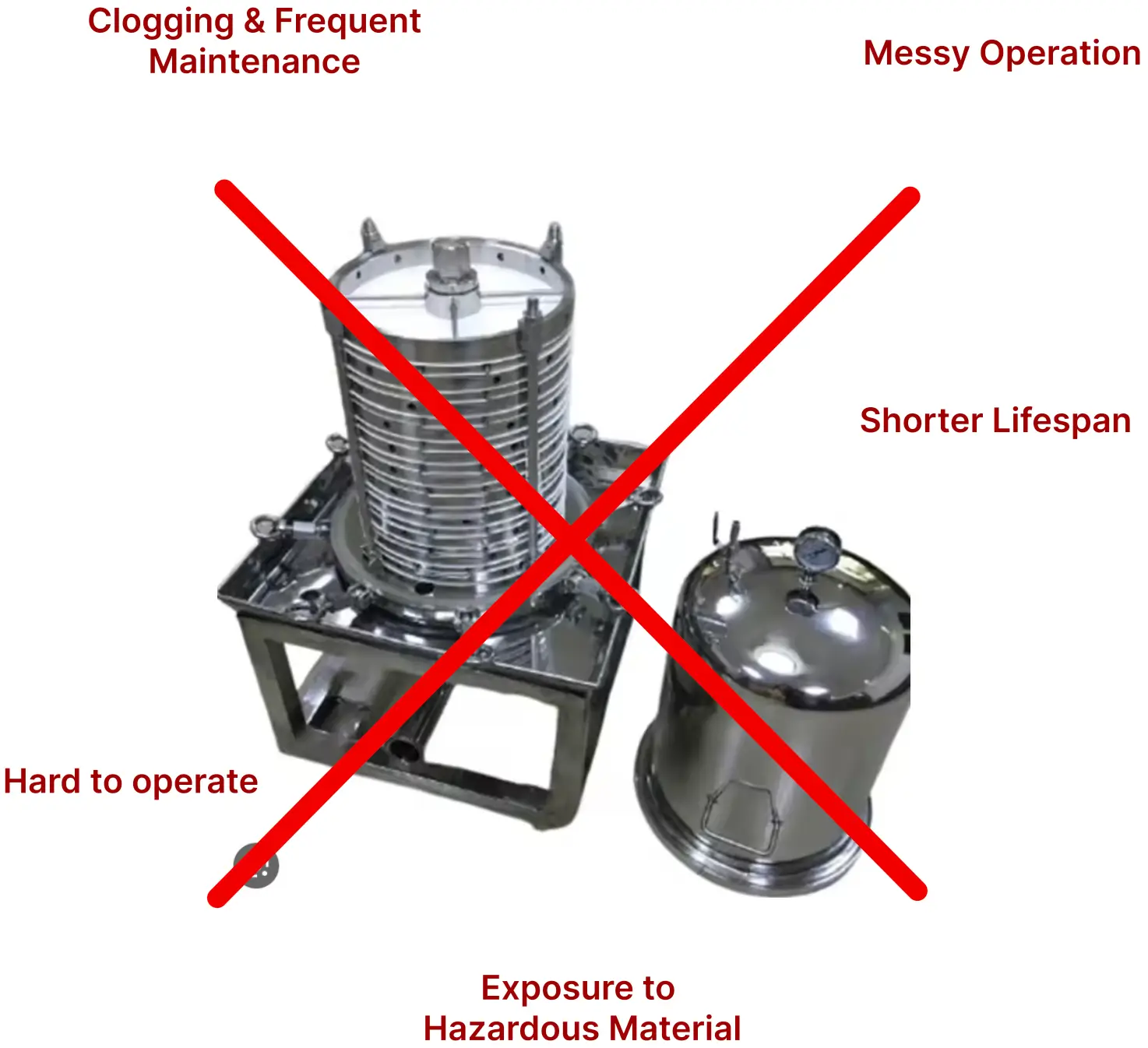

Say No to Sparkler Filters

Contufilt-AC filters offer an extended operational life. The open-channel filter media is resistant to clogging, ensuring consistent performance and reducing the frequency of replacement.

The Contufilt-AC system features a backwashable design that allows in-situ cleaning of the filter elements without opening the system.

Contufilt-AC is a fully enclosed filtration system, protecting operators from exposure to hazardous materials and improving workplace safety.

Ideal For

Activated carbon particle filtration, replacing traditional sparkler filters and reducing operational risks.

Viscous fluid filtration for effective particle removal.

Solids removal and liquid polishing for high-clarity applications.

Ion exchange resin filtration

Blogs

Contufilt - AC

Filtration and Separation

Want to learn more about the technology?

Latest Brochures

Contufilt-AC

Download