- Home

- About

- Industries

- Products

- Wastewater Treatment

- Conventional Effluent Treatment: AQUASEP

- Toxic Refractory < 60,000 COD Removal: Catalytic Hydro-oxidation CHD-Ox

- Wet Air Oxidation for TOXIC > 60,000 COD : THERMOX

- Nanobubbles in Water Treatment: NANOPOREX-E

- Chemical-Free Cooling Tower Technology – A Sustainable Solution: ZEPHYR

- Membranes in wastewater Treatment: PROMEM

- TSS removal and Product recovery using Ceramics: PORESEP

- Heavy Metals and Trace Contaminant removal using Resins: SORBION

- Improving Efficiency of your sand bed filters: NANOMATRIX

- Choosing the Right technology for Wastewater treatment: Wastewater Treatability Studies’

- Chlorine-Divoxide Sanitising of Wastewater: DIVOXIDE

- Reduce/Recover Oil from Wastewater: DISORB

- Produced Water Treatment: PWT

- Non Biofouling Membranes in wastewater Treatment: PROMEM-B

- Vapozem

- Separation Sciences

- Precious Metal catalyst Filtration: CONTUFILT – M

- Activated Carbon Filtration: CONTUFILT-AC

- Raney Nickel Catalyst Filtration: CONTUFILT-RN

- Hot Gas Filtration: CONTUFILT – MH

- Ceramic Dynamic Membrane Filtration: PORESEP

- Reactor Range | Enhancing and Optimising Chemistries: REACTFLOW

- Alternate to Continuous Distillation / Rectification: ROTASEP

- Liquid-Liquid Extraction Mixer Settler: SEPARIX

- Ion Exchange-based RESINS: SORBION

- Pervaporation: Dehydrating Solvents and Separating Mixtures: SOLVOSEP

- Molecular Separation by Membranes: Recovery and Isolation: PROMEM

- Colour / Organics / VOC Removal: CARBOSORB

- Nano-Bubbles Improve Process Efficiency: NANOPOREX

- Vapozem

- Wastewater Treatment

- Resource

- Contact Us

Odor control/ removal in Sewage systems, Stormwater pipelines and STP using NANOPOREX nano bubbles

In recent times, the increase in the demand for urban development has increased, due to which wider attention is being paid to problems of odor in sewage. Due to rapidly increasing population, growing production demands, expanding human activities, the massive discharge of domestic and industrial wastewater has led to the release of odorous pollutants into drainage pipelines, that is making the odor from the drainage pipelines a widespread social concern.

There is nothing more suffocating than bad odor. They can make us feel sick and they can ruin our day. Bad smells can come from many different sources, but most common sources are sewage systems, stormwater pipelines and STP.

Causes of odor from sewage, stormwater pipelines & STP

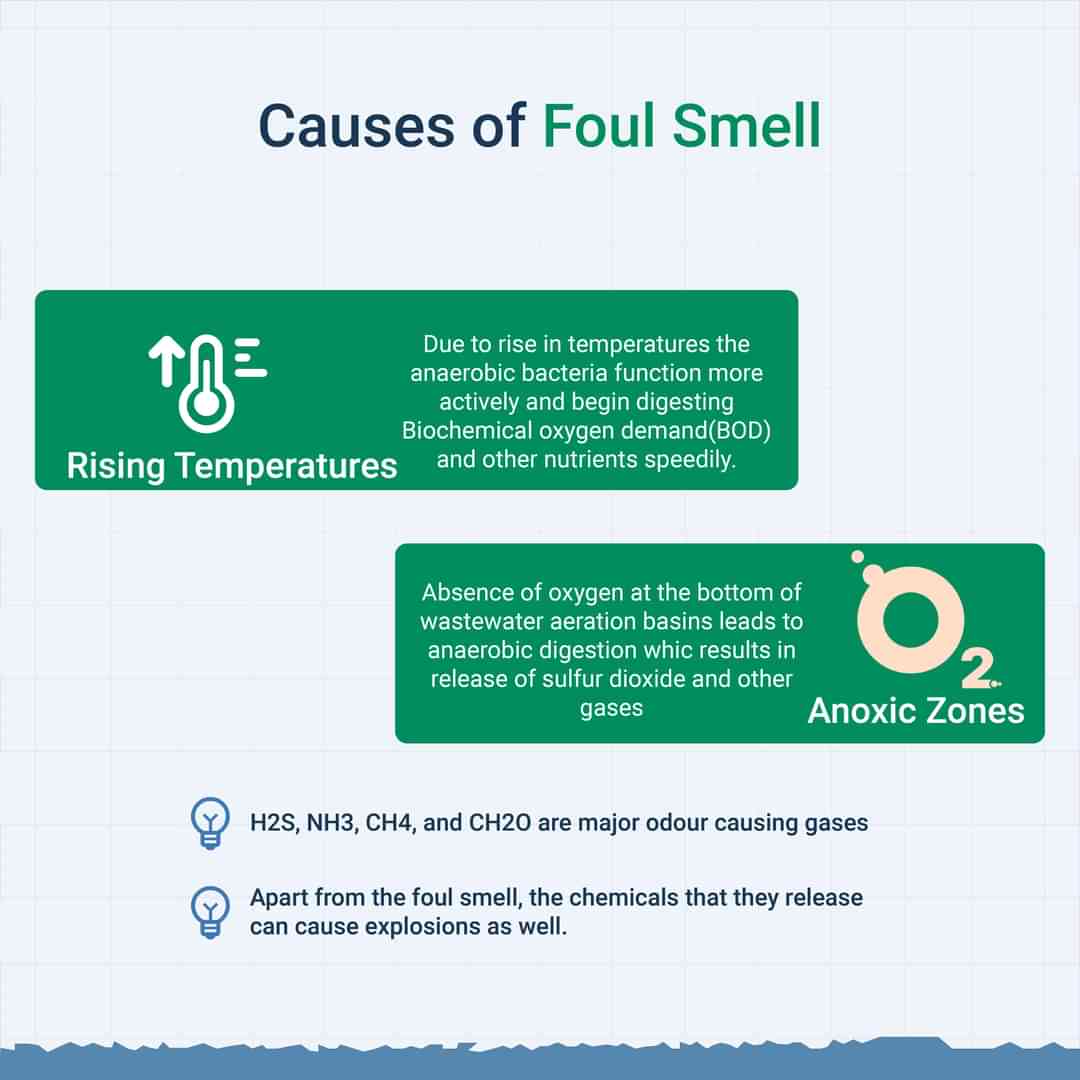

As the temperature increases during summer, the temperature of wastewater also increases. Due to this the anaerobic bacteria function more actively and begin digesting Biochemical oxygen demand(BOD) and other nutrients speedily. Them being active is directly proportional to the increase in temperature.

And hence sewage systems, stormwater pipelines and STP have a strong nasty smell in summer compared to other seasons . Both, rise in temperature and low oxygen levels can create anoxic zones at the bottom of wastewater treatment basins.

The main cause of bad or nauseous odor coming from sewage systems, stormwater pipelines and STP is sulfur dioxide and many other noxious gasses released during anaerobic digestion the smell of which is similar to that of rotten eggs. Anaerobic digestion is a slower process compared to aerobic processes, which means the underwater treatment process is not carried out to emit to its optimum.

Effects of Untreated Sewage Water

When proper attention isn’t provided towards sewage, the flow of sewage waste, which exceeds the maximum capacity of valves or pipelines, then the overflow of sewage water occurs. As sewage overflows from cracked manhole covers and gaps, it causes water to pool on the road and diffuses an unpleasant odor into the atmosphere. Hence the infrastructure of these pipelines should be strengthened.

Apart from the foul smell they emit, the chemicals these odorous substances create can cause explosions as well. When hydrogen sulfide and methane produced by biofilms in sewers mix with air, they can result in an explosion.

Wastewater treatment plants are known for emitting high amounts of ammonia, H2S, NH3, CH4, and CH2O which are major causes for causing odor in and around the area.

Odor Control Systems and Its Poor Maintenance In Dubai

The Dubai Municipality did not have an odor monitoring system that could detect the parameter levels of such harmful gasses in many of the countries Water Treatment Plants.

Despite being a water-scarce region, only 5% of the water used in the UAE is treated wastewater. The primary sources of water are groundwater and desalinated seawater. Expanding the use of treated wastewater could significantly alleviate water scarcity and reduce reliance on expensive desalination processes. The Dubai Waste Treatment Centre, a significant waste-to-energy project, aims to convert waste into energy. It has an impressive efficiency rate of 32% at a temperature of 27°C. However, challenges remain in ensuring that waste treatment processes are environmentally friendly and minimize emissions.

Dubai Municipality maintains two main sanitation plants: one in Al Awir and another in Jebel Ali. These plants play a crucial role in wastewater treatment within the emirate.

But additionally, there needs to be more modern wastewater treatment techniques to facilitate the demands of increasing population.

The sewage network in Saudi Arabia covers about 50% of the total wastewater generated. As of 2018, the country has approximately 5.6 million cubic meters per day of wastewater treatment capacity, with additional capacity under construction and some planned for decommissioning.

Saudi Arabia's Progress in Wastewater Treatment: Opportunities for Improvement

In examining wastewater treatment coverage across Saudi Arabia, it’s clear that there’s room for growth. Daman city leads the charge with 78% of wastewater undergoing treatment, while Riyadh and Jeddah stand at 60% and 50%, respectively. Efforts are indeed underway to bolster these numbers.

While both Dubai and Saudi Arabia have commendable waste-to-energy initiatives and sustainable water management practices, there’s still work to be done to enhance resilience and environmental stewardship.

Nanobubbles hold great promise for the future, particularly in sewage systems, stormwater pipelines, and sewage treatment plants. Despite this potential, Middle Eastern countries, including our own Dubai and Saudi Arabia, have yet to fully explore the transformative benefits of nanobubble technology.

Nanobubbles the only and effective solution of wastewater treatment systems?

Increasing oxygen in wastewater treatment systems is one of the most effective ways to combat the foul odor released as anaerobic digestion will slow down. If proper circulation of waste water occurs, the amount of oxygen in water will automatically be increased. This in turn will support odor free aerobic respiration. Surface aerators have limited reach, they only can go till the shallow areas of water treatment system and cant go deeper, because of which depth of the system lacks oxygen supply increasing the foul.

Nanobubble technology has indeed emerged as a revolutionary solution in wastewater treatment. Nanobubbles are incredibly small gas bubbles, typically less than 200 nanometers in diameter. Due to their small size, nanobubbles have a high surface area-to-volume ratio, which enhances gas transfer efficiency. Due to which nanobubbles can be integrated into existing treatment infrastructure to enhance pollutant removal. They are particularly effective in treating organic compounds and ammonia.

Our nanobubble technology increases the oxidation not only on the surface but even at the bottom of the aeration basins which increases the digestion of aerobic digestion hence decreasing the activity of anaerobic digesters. Higher efficiency is achieved through nanobubbles and this method also improves the water quality. Nanobubble generators achieve oxygen transfer rates upto 85% more than other technologies.

NANOPOREX bubble generators introduce finely dispersed gas bubbles into water, greatly improving mixing and increasing the available surface area for gas-liquid mass transfer. This innovative method boosts efficiency in chemical and biological processes. Compared to conventional Industry methods like drilled pipes or diffusers, the Nanoporex bubble generator increases mass transfer surface area by almost 1000 times.

The gas is dispersed as a fine mist of bubbles, expanding the mass transfer area. This heightened surface area enhances the efficiency of gas-liquid mixing when liquid-gas interface reactions take place. NANOPOREX bubble generators employ cavitating devices to produce billions of fine bubbles.

Revolutionary Gas-Injection Technology: Bubble Systems’ gas-injection tech transforms the flotation process.Energy Efficiency: It cuts energy use by 10%-20% compared to standard methods. Environmental Compliance: Our unique properties ensure adherence to environmental regulations.

This significantly increases the surface area in a two-phase reaction between gaseous and liquid, resulting in rapid and efficient mass transfer. Bubbles’ negative surface charge stops them from joining together, ensuring effective interaction. Operators can adjust the gas-injection rate to control bubble size and rise rates. Bubbles boost collision rates, cutting down on the amount of chemicals required for flotation.

Industries

Wastewater Treatment

Separation Sciences

Contact

Sign in for latest updates

Stay informed with the latest updates from Diva Envitec! Sign up for our newsletter to receive exclusive news, insights, and case studies directly to your inbox.

Copyright © 2024 Diva Envitec

Terms of Service

Privacy Policy

Industries

Wastewater Treatment

Separation Sciences

Contact

Sign in for latest updates

Stay informed with the latest updates from Diva Envitec! Sign up for our newsletter to receive exclusive news, insights, and case studies directly to your inbox.