Produced Water Treatment using DiSorb Separator - Diva Envitec's Sustainable Innovation

For the offshore oil and gas industry, managing produced water is a formidable challenge. The vast quantities of water generated during oil and gas extraction must undergo efficient treatment before disposal. While the preferred option is re-injection into wells, stringent environmental standards often necessitate discharge into the sea. However, the primary concern is removing hydrocarbons from produced water.

The Produced Water Management Challenge

In ecologically sensitive regions mandate that hydrocarbon levels in discharged water must not exceed 30 ppm. Facilities exceeding this limit face costly scrutiny, including daily sample transportation for onshore analysis, resulting in financial and environmental burdens. Effective on-site produced water treatment is paramount. Amongst all the challenges in industrial wastewater recycling systems, PWT is a challenging application.

DiSorb Separator: A Game-Changing Solution

Choosing the right produced water filtration solution can be a game-changer. Diva Envitec Pvt Ltd's groundbreaking DiSorb Separator emerges as a game-changer for the oil and gas sector. Produced water treatment allows meeting sustainable water conservation through industrial wastewater reuse

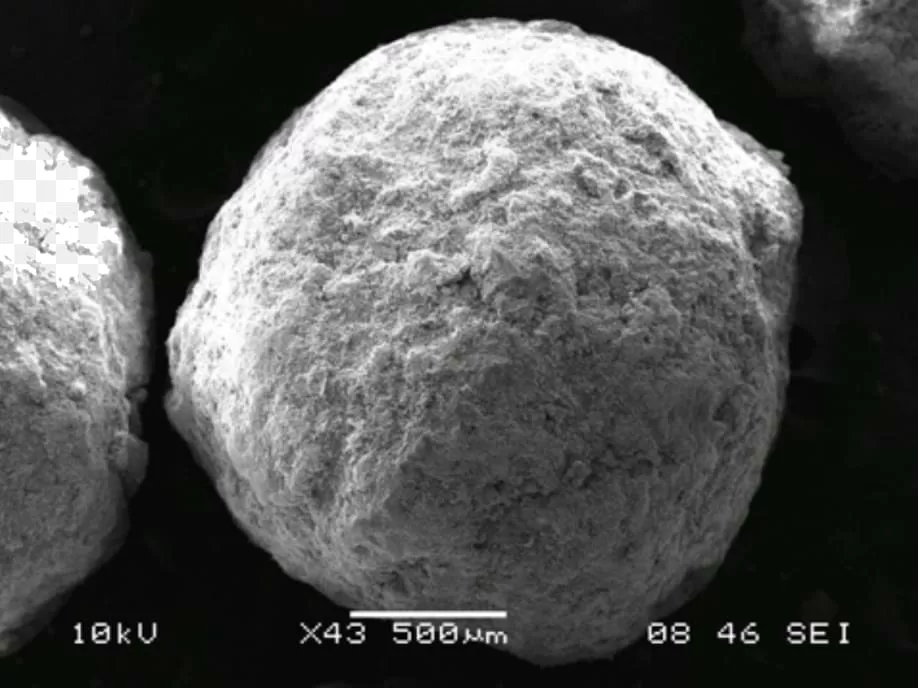

The DiSorb Separator employs a highly Oleophobic medium, facilitating oil coalescence in interstitial spaces while capturing Total Suspended Solids (TSS) without blockages. This system excels at removing oil and TSS, achieving higher removal rates with heavier oil loads. DiSorb's robust medium effectively handles these challenging materials:

- 1-300 ppm of Oil and TSS: Over 99% removal of both oil and TSS.

- 300-700 ppm of Oil and TSS: 99% removal of both oil and TSS.

- 700-3000 ppm of Oil and TSS: Efficiently manages intermittent loads with shorter filtration cycles.

Operational upsets causing significant oil level increases have no adverse effect on the DiSorb media, except for a swift backwash step. This process resembles a Dual Media Filter, allowing easy retrofitting with minimal structural changes, converting your existing Nutshell Filter into a DiSorb Oil Removal Separator.

Essential Oil Recovery and High-Temperature Operation

Apart from substantial oil and TSS removal, the DiSorb Separator offers essential oil recovery. It operates at temperatures as high as 85°C, accommodating short-term excursions up to 100°C. This innovative technology in industrial wastewater recycling is a game-changer across multiple sectors, including Oil and gas, Edible Oil, and Port - Oil Spills.

What sets DiSorb apart are its high-performance results. It reduces hydrocarbon content in produced water well below 30 ppm, often reaching as low as 5 ppm, or even less, effectively providing clean water. In India, the norms are much relaxed, but soon we will have to ensure compliance as met by OSPAR and future-proofs against potential decreases in hydrocarbon thresholds.

Plug-and-Play Efficiency

The DiSorb system is notably user-friendly, requiring minimal manual intervention for filter changes. It's plug-and-play, requiring straightforward installation and activation. Moreover, its filtration unit operates efficiently with a standard pump, eliminating the need for high-powered pumps. The DiSorb media effectively recovers water and oil from oily wastewater by removing TSS, offering a reliable, straightforward, and efficient solution.

By replacing your existing oil removal filter media with DiSorb, you can unlock substantial savings and enhance operational efficiency. DiSorb guarantees superior filtration while minimizing lifecycle costs without compromising water quality.

The Trusted Solution for Produced Water Filtration

For businesses grappling with produced water challenges offshore, DiSorb is the go-to solution. It offers a game-changing approach to produced water filtration, simplifying the fulfillment of environmental obligations. It’s not just effective but also easy to operate, significantly reducing manual intervention.

DiSorb is a pioneering solution that helps meet existing OSPAR regulations while future-proofing your produced water filtration endeavors. It's an ideal choice for offshore facilities, providing tailored solutions, requiring minimal maintenance, and delivering dependable results. Furthermore, the DiSorb vessels are easy to replace, and the media can be recycled, making it a sustainable choice for produced water filtration.

DiSorb from Diva Envitec Pvt Ltd presents an opportunity for oil and gas production operations to eliminate costly scrutiny and meet environmental obligations without compromise. It accomplishes the task effectively and straightforwardly, revolutionizing the field of produced water filtration, simplifying intricate processes, industrial water recycling, and aiding businesses in securing a more sustainable future.

Contact

Industry