Why we need the circular economy model in chemical engineering

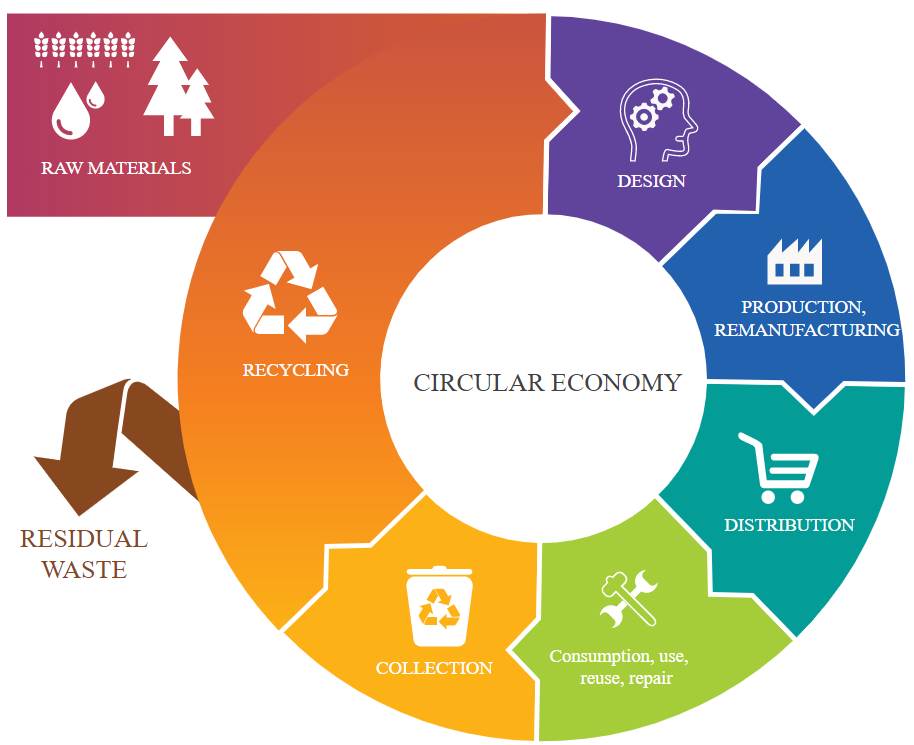

A circular economy involves the sharing, reusing, repairing, refurbishing, redesigning, and recycling of materials and products for ‘as long as possible’ to reduce our use of the world’s resources, cut down waste generation, and ultimately diminish carbon emissions.

The world may be progressing super-fast, but the pace has led to an extraordinary number of challenges: soaring inflation, geopolitical tensions, supply issues, climate change, and untenable resource consumption.

The last is something we all really need to do something about. For we have only one Mother Earth.

A Bain and Company study reveals that humans are currently using the “equivalent of 1.75 times the earth’s natural resources each year”.

The Circularity Gap Report 2022 puts things into better perspective – the global use of materials has outstripped the growth of population in 50 years.

Consumption was 28.6 billion tonnes in 1972

It rose to 54.9 billion tonnes in 2000

Consumption surpassed 100 billion tonnes in 2019

The Bain study offers further frightening statistics: “Our take-make-waste economy consumes 100 billion tonnes of materials a year and wastes over 90%.”

“Rising waste levels are accompanying the rapid acceleration of consumption: ultimately, over 90% of all materials extracted and used are wasted. Or, on the flip side, only 8.6% make it back into our economy. And it's getting worse: in only two years, global circularity wilted from 9.1% in 2018 to 8.6% in 2020,” it says.

What is the solution?

Experts around the world are united in their answer: a circular economy.

https://www.weforum.org/

As opposed to the linear economy model of production and consumption we have lived with so far, a circular economy involves the sharing, reusing, repairing, refurbishing, redesigning, and recycling of materials and products for “as long as possible”.

This aims to reduce our use of the world’s resources, cut down waste generation, and ultimately diminish carbon emissions.

Also known as circularity, this way of life envisages decoupling economic growth from resource consumption.

Companies can work towards a circular economy in many ways: they can open the loop by conserving materials, using sharing economy platforms, offering products as a service, increasing the lifetime of a product by repair and reuse, and closing the loop by recycling.

The chemical engineering connection

Chemical engineering works with raw materials to ensure their transformation into final useful products. It manages flows and transformations of materials and energy in industrial plants. This is the engineering discipline used in all process industries, including chemicals, petrochemicals, energy, water, pharmaceuticals, food, and plastics.

Materials provided by the industrial chemical sector are used in almost 95% of all manufactured products. The sector also plays a huge role in all kinds of recycling, be it mechanical, organic, or chemical, which further enmeshes it into the circular economy.

It is natural that the sector, which helps make materials and products more durable to extend their lives and reduce waste and demand for new products, must play a starring role in helping the world transition away from the unsustainable “take-make-use-waste” model to the “grow-make-use-restore” one.

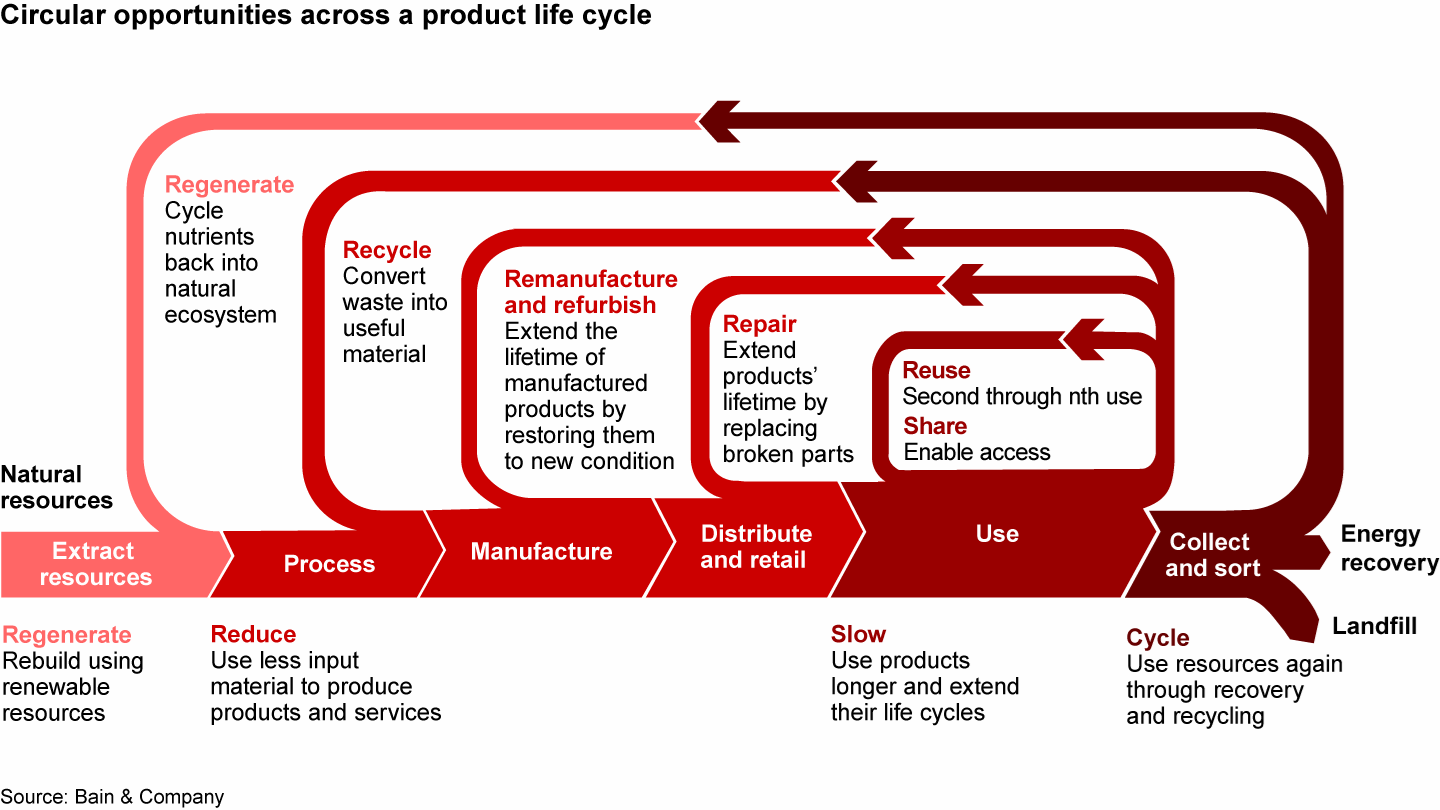

In Perspectives on circular economy in the context of chemical engineering and sustainable development, a paper published on Science Direct, the authors write that the aim of the circular economy is to make “production processes more sustainable, maintain materials in a useful state in products for as long as possible, and avoid material losses, dissipation or hibernation, and emissions to the environment”.

How can we get there? By making use of efficient technologies, effectual use of resources, and minimising waste/emissions.

What can we do to achieve this? The paper puts forth a few pointers:

Keep the circular loop in mind while designing processes and regenerative systems. This means minimising inputs, energy leaks, emissions, and waste, by narrowing and closing energy loops, by encouraging reusing, remanufacturing, refurbishing, and recycling.

Convert waste streams into value-added products such as food, feed, bioenergy, and bio-based products.

Select the best-in-class process technologies to cut consumption of water and energy.

Promote the use of renewable sources and use strategies to increase efficiency and recycling of non-renewable resources.

The path ahead

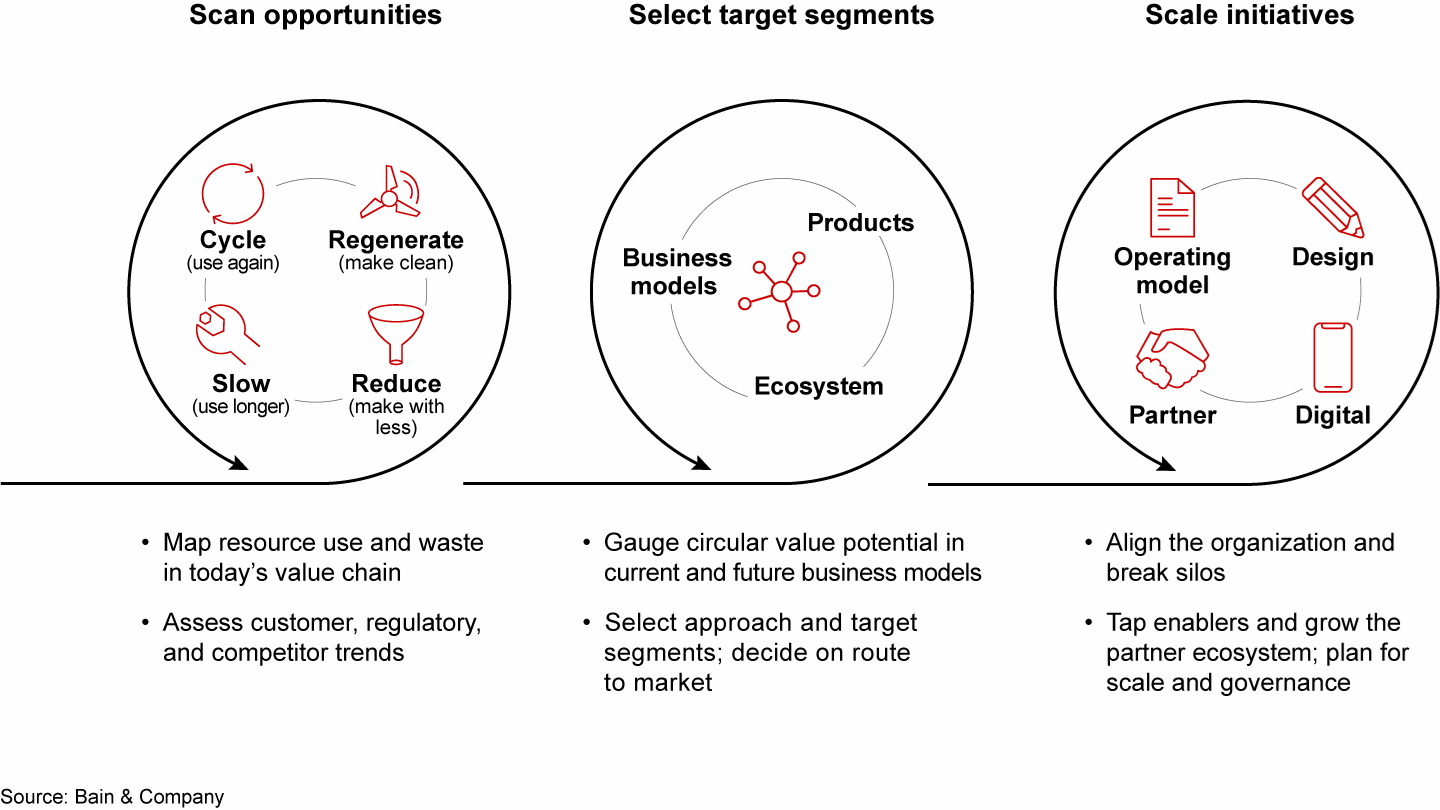

Sector leaders and thinkers have responded to the challenges, with the chemical industry now rethinking and reworking models to bring change.

There is no fixed path to reaching a circular chemical economy. It will involve a network of innovators, businesses, companies, policymakers, financiers, and consumers, who come together with a new approach and work alongside to meet circular economy targets. Collaboration will be key to create and sustain circular ecosystems, and stakeholders must keep the Triple Bottom Line - environment, economic, and social sustainability – in mind.

The time for everyone to work towards a circular economy is NOW.

Early movers will gain substantial and strategic advantages, and will be poised to disrupt industries and markets. World and business leaders believe that companies with pioneering experience in circularity will be in the strongest position to sustainably meet customer needs.

Diva Envitec is also working to meet the many challenges of the circular economy by focusing on sustainability and closing loops. We believe the future of our planet depends on it.

Contact

Industry