- About

- Industries

- Products

- Wastewater Treatment

- Conventional Effluent Treatment: AQUASEP

- Toxic Refractory < 60,000 COD Removal: Catalytic Hydro-oxidation CHD-Ox

- Wet Air Oxidation for TOXIC > 60,000 COD : THERMOX

- Nanobubbles in Water Treatment: NANOPOREX-E

- Chemical-Free Cooling Tower Technology – A Sustainable Solution: ZEPHYR

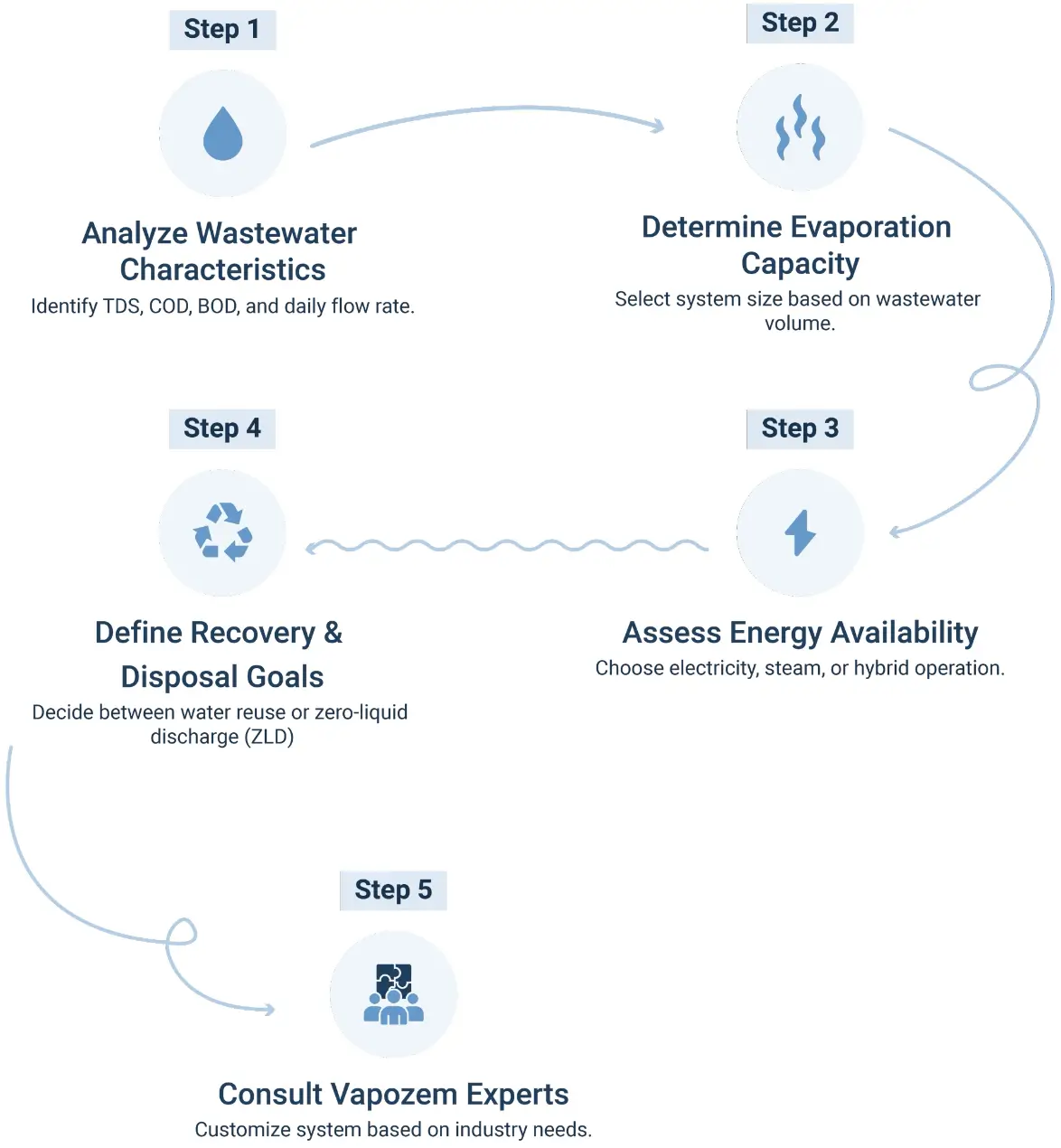

- MVR for ZLD: Vapozem

- Membranes in wastewater Treatment: PROMEM

- TSS removal and Product recovery using Ceramics: PORESEP

- Heavy Metals and Trace Contaminant removal using Resins: SORBION

- Improving Efficiency of your sand bed filters: NANOMATRIX

- Choosing the Right technology for Wastewater treatment: Wastewater Treatability Studies’

- Reduce/Recover Oil from Wastewater: DISORB

- Produced Water Treatment: PWT

- Non Biofouling Membranes in wastewater Treatment: PROMEM-B

- Advanced Bioaugmentation Culture: BIOPORE

- Cavitation using Ultrasonics: RUSONICS-E

- Oxygen Generator System for Industries: OXYLIFE

- Process Solutions

- Precious Metal catalyst Filtration: CONTUFILT-M

- Activated Carbon Filtration: CONTUFILT-AC

- Raney Nickel Catalyst Filtration: CONTUFILT-RN

- Hot Gas Filtration: CONTUFILT – MH

- Biosolids removal using ceramics: PORESEP

- MVR for ZLD: VAPOZEM

- Ion Exchange-based RESINS: SORBION

- Dehydrating solvents by Zeolite Membranes: SOLVOSEP

- HiGee Continuous Distillation: ROTASEP

- Molecular Separation by Membranes: PROMEM

- Filtration & Separation

- Precious Metal catalyst Filtration: CONTUFILT – M

- Activated Carbon Filtration: CONTUFILT-AC

- Raney Nickel Catalyst Filtration: CONTUFILT-RN

- Hot Gas Filtration: CONTUFILT – MH

- Ceramic Dynamic Membrane Filtration: PORESEP

- MVR for ZLD: Vapozem

- Nano-Bubbles Improve Process Efficiency: NANOPOREX

- Alternate to Continuous Distillation / Rectification: ROTASEP

- Liquid-Liquid Extraction Mixer Settler: SEPARIX

- Ion Exchange-based RESINS: SORBION

- Pervaporation: Dehydrating Solvents and Separating Mixtures: SOLVOSEP

- Cartridges & Filter Bags: FLOWSEP™

- Molecular Separation by Membranes: Recovery and Isolation: PROMEM

- Colour / Organics / VOC Removal: CARBOSORB

- Oxygen Generator System for Industries: OXYLIFE

- RUSONIC – Sonochemistry

- Magnetic Separator Technology: MAG-Filt

- Wastewater Treatment

- Resource

- Contact Us

Industries

Wastewater Treatment

Process Solutions

Sign in for latest updates

Stay informed with the latest updates from Diva Envitec! Sign up for our newsletter to receive exclusive news, insights, and case studies directly to your inbox.

Copyright © 2025 Diva Envitec

Terms of Service

Privacy Policy

Industries

Wastewater Treatment

Process Solutions

Sign in for latest updates

Stay informed with the latest updates from Diva Envitec! Sign up for our newsletter to receive exclusive news, insights, and case studies directly to your inbox.