High COD (Chemical Oxygen Demand) waters are difficult to treat. Biological systems fail due to this COD toxicity. The antibiotics, pesticides, insecticides and micro-pollutants pose a considerable risk to MBBR. CHD-OX Treatment helps increase the biodegradability of wastewater before it enters the MBBR.

CHD-OX – Catalytic HyDro-Oxidation, a proprietary technology of Diva Envitec Pvt Ltd, enhances the production of OH radicals using strong oxidants and our CHD Catalyst. The formation of strong OH radicals breaks the refractory and recalcitrant long-chain COD into more biodegradable elements. CHD reduces and breaks long-chain toxic and refractory COD. The final effect is an increase in biodegradability of the wastewater before entering into the MBBR. The MBBR functions more stably. CHD can be applied to all existing CETP and ETP plants

Many industrial wastewaters can be treated using Catalytic Hydro-Oxidation; it is used as a prelude for biological Treatment.-

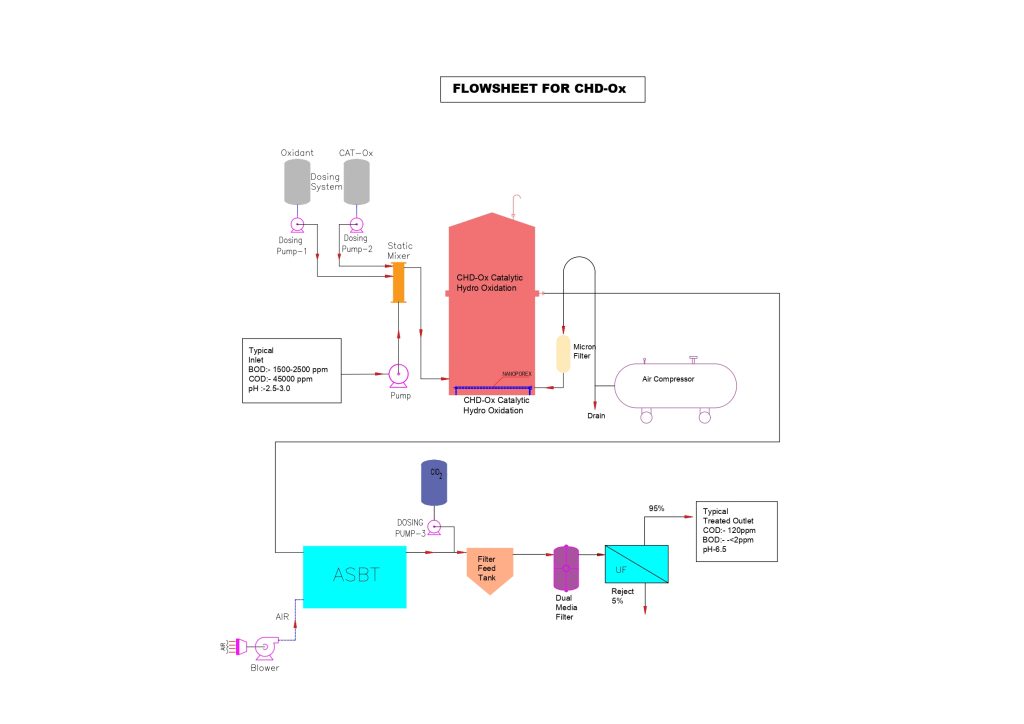

Process Operation

Catalytic Hydro-oxidation uses a Batch Reactor or Continuous Radial flow reactor for the Treatment. The catalyst, which is nano-particles of complex metals, generates Hydroxyl Ions in the presence of oxidants.

NANOPREX micronisers assist the operation by creating a cavitation effect in the main water stream. In addition, the CHD-Ox Treatment can degrade volatile acids and other organics present in the condensate into simpler, non-toxic molecules. We continually develop new catalyst formulae to enhance the rate of degradation in the process based on wastewater chemistry from different industries.

Features and Advantages

- Fast BOD, COD and Odour removal

- Broad-spectrum; acts against many types of organics present in the water

- Retrofit in Existing ETP

- Low retention time is usually 4-6 hours.

- Time-saving process over conventional biological Treatment

- Hassle-free and easy to control process conditions

- Helps to achieve the zero liquid discharge (ZLD) target in the industry

- A catalyst for both Reducing and Oxidising environments. The catalyst triggers the Hydroxyl Ion generation

- Low footprint

Technical Specification

- Reactor of SS or Coated MS

- Nanopores Micronisers

- CPVC piping

- Air Compressor

- Oxygen generator

- Catalyst Dosing Pumps

- Oxidant Dosing Pump

Application

- Recalcitrant COD

- Toxic COD

- STP

- Pesticide

- API ETP

- Tanneries

- Dye Effluents

- Textile Effluent

- Distillery

- Condensate Polishing in Sugar

- Condensate Polishing in distillery

Contact

Industry